The GoPal® Solution

at Thomas Regout International B.V

GoPal delivers candy and drinks for the employees at Thomas Regout during the COVID-19 age.

- Company: Thomas Regout International BV

- Country: Netherlands

- Industry: Electrical & Electronic Manufacturing

- Employees: 201-500

- Internal pallet transport

- Ensured social distancing during COVID-19

- Reduced risk of infection among employees

- Automated internal pallet transport

- Minimal risk of COVID-19 infection

- Reduce the need for longer shifts

- Keep production up and running

In short:

Thomas Regout International B.V. (Netherlands) offers a broad range of sliding solutions that help move your application in any direction: horizontally, vertically, and diagonally.

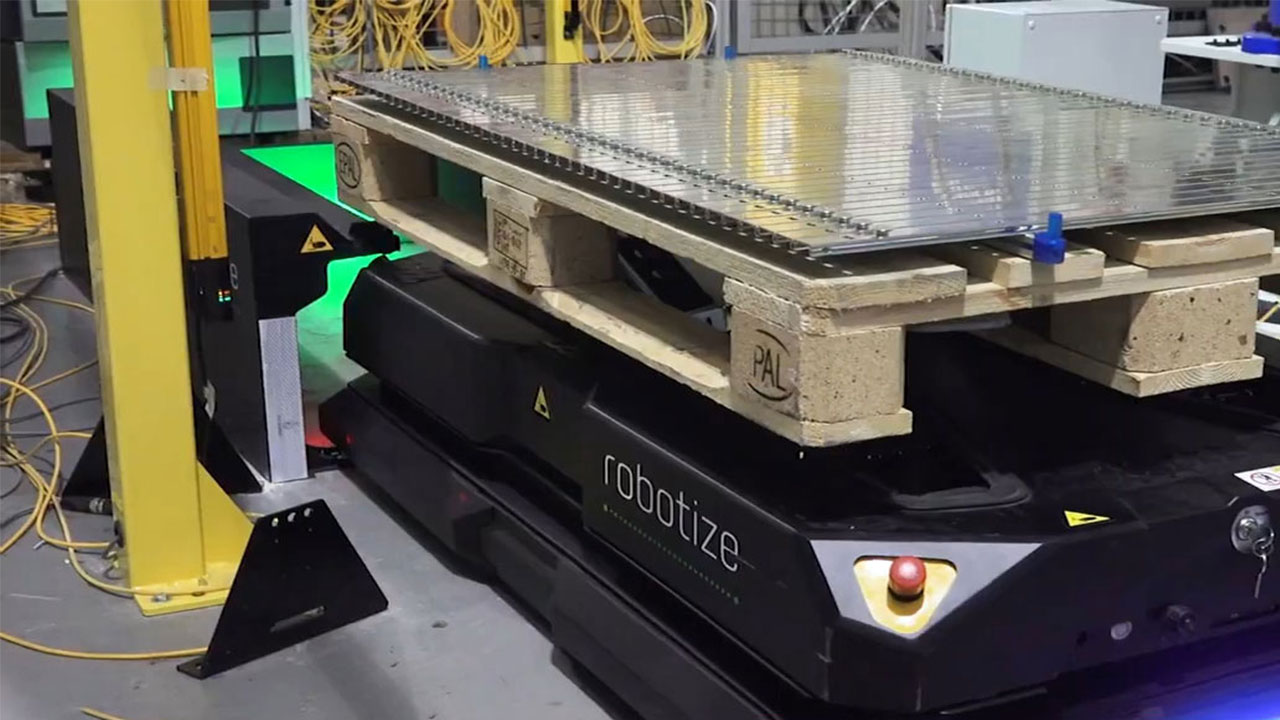

In order to remain the best partner in telescopic slides, Thomas Regout has made some major improvements in their factory in Maastricht. Among other things, the company decided to run a long-term rental period of a GoPal 400 Autonomous Mobile Robot (AMR) to determine if a GoPal solution was the right choice for their business. “We came to the conclusion that it would be interesting to set up a rental agreement”. The company is very enthusiastic about the GoPal solution and have now installed and deployed three GoPal AMRs.

The challenge

Like many other companies, Thomas Regout International B.V. identified the need to comply with risk-reducing measures to minimize the spread of COVID-19. Fortunately, the autonomous mobility of the GoPal 400 helped the employees at Thomas Regout comply with the COVID-19 restrictions, such as social distancing. Unfortunately, COVID-19 has changed the way we do business worldwide. Companies need to make sure that their employees are safe and motivated during these tough times. Using creativity, Thomas Regout took advantage of the autonomous mobility of the GoPal 400 and used it to deliver candy and drinks to their hard-working employees.

The solution

Currently, Thomas Regout International B.V is using two GoPal AMRs: one in the Netherlands and one in Spain at one of their partners.

The company recognizes the many benefits that the GoPal solution brought to their internal pallet transport. “The GoPal AMRs are a great advantage in our factory,” explains Raoul Frenken. Therefore, the collaboration between Thomas Regout International B.V and Robotize will continue. The company plans to add 3-4 additional AMRs to their company. “We already talked with Robotize about our future plans,” says Raoul Frenken.

Not only has the GoPal solution improved the internal pallet transport at Thomas Regout International B.V., but has also been a great support in the fight against COVID-19. Due to their agile and intelligent navigation as well as safety aspects and ability for autonomous navigation, the GoPal AMRs supported the workers physically with internal pallet transport as well as morally with candy and drinks.