The GoPal® solution

at Marquardt

- Company: Marquardt

- Site: Sibiu, Romania

- Employees: +10.000 (globally)

- Industry: Automotive.

- Website: www.marquardt.com

- Automated pallet transportation both within production area and logistics area

- Fleet of nine GoPal E24 AMRs

- +50 Pallet Stations

- Charging Stations

- Pallet Sensors

- IO Box

- Virtual Buttons

- Brownfield deployment with narrow lanes and passages

- Safe, reliable. and efficient pallet transportation

- Easily scaled from six to nine AMRs

- Travelling more than 160 km // 100 miles per day

- Handling +600 orders per day

- Mitigating labour shortages

In short

Marquardt is one of the world’s leading manufacturers of electromechanical and electronic switches and switching systems used in the automotive industry. This includes Human-Machine Interface devices such as physical control buttons, steering wheels, electronic gear shifters, sensors, battery management systems, and driver authentication systems.

In 2003, Marquardt opened their first plant in Romania, which has since undergone several expansions.

The challenge

The total production and logistic area at Marquardt’s plant in Sibiu, Romania, covers 25.000 sqm (270,000 sq. ft), which means having to transport a lot of materials very long distances. Before automating their internal material transportation, Marquardt used tugger trains and pallet jacks. Other challenges included COVID restrictions and difficulties in attracting and retaining labour.

This led Marquardt to look for alternatives, including automating their internal material transport.

The solution

Marquardt tested several automation solutions, and quickly decided that the best fit would be the GoPal AMR solution. One of the key factors was the ability of the GoPal AMRs to operate in narrow passages and to pass through tight restrictions.

In fact, Marquardt were so impressed with the performance of the GoPal AMRs that the company decided to not only deploy the GoPal solution within their production environment, but also to cover all their intralogistics operations:

• from storage area to reception area, to the warehouse storage blocks

• line feeding with components

• move empty packaging from the warehouse to the assembly lines

• pickup finished goods from assembly lines and deliver to the warehouse and outbound area

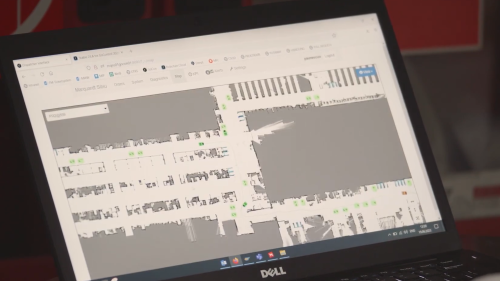

Marquardt created more than 80 “constellations” in the GoControl Fleet Management System (FMS), where one constellation means one pick-up point with multiple delivery points. In total, Marquardt currently has a network of 52 fully automated material transportation routes.

Once a pallet is ready for pick-up, the operator simply selects the applicable delivery point (Virtual Buttons) on a touchscreen. A GoPal E24 arrives, picks up the pallet and proceeds to the applicable delivery point.

The GoControl FMS also shows the location of the robots on a map in real-time, provides order status, as well as the ability to quickly reprioritize tasks on-the-fly depending on Marquardt’s requirements at any given time.

Marquardt deployed the following GoPal solution:

• GoControl FMS

• Initially six GoPal E24 AMRs, which were subsequently scaled with an additional three robots for the current total of nine GoPal E24 AMRs

• +50 Pallet Stations with Virtual Buttons for manually summoning robots for pallet pick-up (and subsequent delivery to a predefined delivery point)

• Charging Stations

• Pallet Sensors

• Conveyor Station

• I/O Box enabling robots to communicate with the existing infrastructure to automatically open doors/gates

“The great thing about the GoPal solution is that it not only provides the robots, but also all the connected accessories such as pallet stations, conveyor stations, call buttons, and I/O Box for door control automation.”

- Octavian Paunescu

Key User GoPal AMRs at Marquardt

The Benefits

The GoPal AMRs travel a distance of more than 160 km // 100 miles per day and handle more than +600 orders per day, but this can easily go higher when required.

“Based on our very positive experience with the GoPal solution, we won't go back to our old method. The GoPal solution works great for us, and we remain close with our Robotize partner, Novomatix, to continuously add new features.”

- Alex Armenean

Warehouse & Material Flow Manager at Marquardt

About Marquardt

Marquardt was founded in 1925 and is based in Rietheim-Weilheim, Germany. The company is one of the world’s leading manufacturers of electromechanical and electronic switches and switching systems. The products of the mechatronics expert are used by many well-known customers in the automotive industry and include operating components, vehicle access, driver authorization systems and battery management systems. The company’s systems are also used in household appliances, industrial applications and power tools. Marquardt Group employs around 10,000 members of staff worldwide at 22 locations in four continents. Turnover in the 2023 financial year was just under 1.4 billion euros. Each year, Marquardt invests around ten percent of its revenues in R&D.

Robotize Partner on this project

Learn more about our Romanian partner.