The GoPal Solution

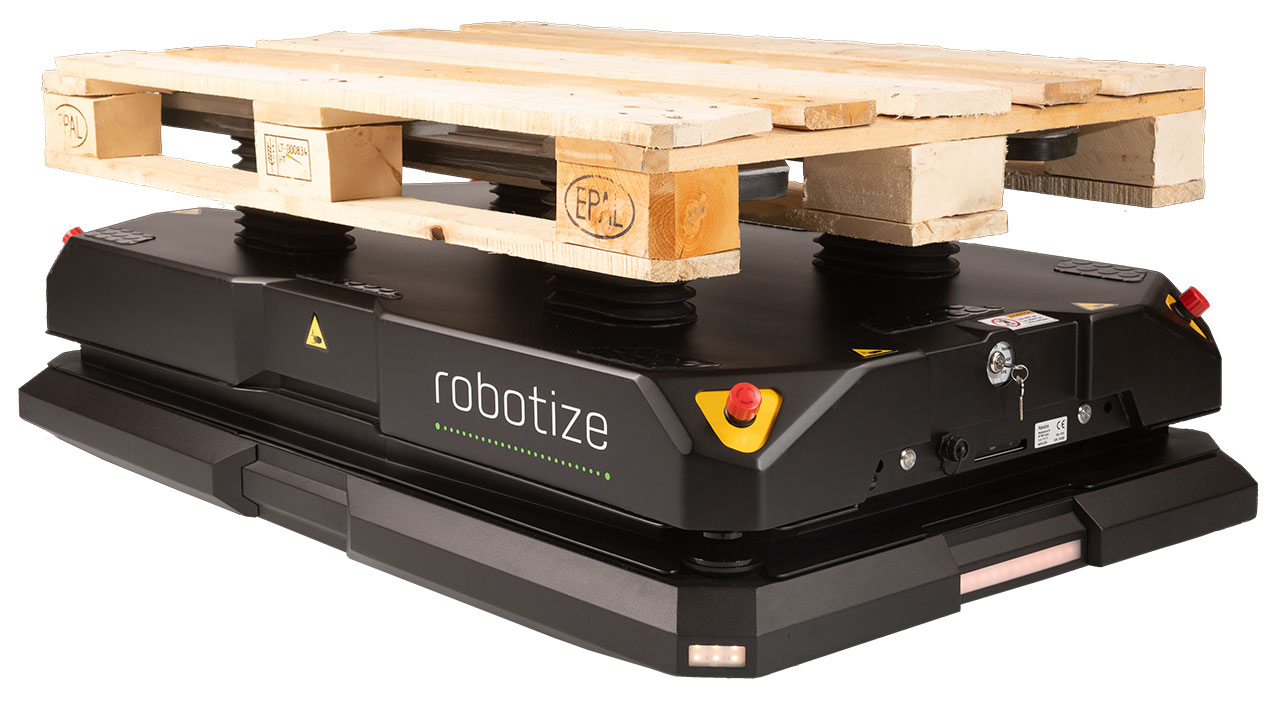

Our range of Autonomous Mobile Robots (AMRs) and accessories set new standards for easy deployment, flexibility and safety when automating your internal material transportation.

Automatically picking up, transporting and delivering pallets and top modules has never been easier and safer. The GoPal solution can be deployed and begin saving you money in a matter of a few weeks with minimum changes to your existing infrastructure or impact on daily operations.

GoPal

Whatever the application, GoPal delivers

GoPal is a highly versatile automation solution for handling heavy workflows 24/7/365. Our GoControl fleet management software enables you to easily manage and track all your AMRs and accessories.

GoPal helps companies easily automate internal transport. The warehouse automation system can be configured for any combination of simple delivery (A to B), complex delivery (A to B, C or D), and production support (A to B, B to C, C to D, etc.).

- GoPal E22

- GoPal E24

- GoPal E24W

- GoPal U22W

- GoPal U24W

- GoPal P35

- ROI within 6-18 months

- Complete end-to-end automation solution

- Increased employee safety

- No damaged goods/infrastructure

- Mitigate labor shortages/retention

- Use data to continuously improve operations

- Maintain your competitive edge

- Cutting-edge pallet and platform AMRs

- Wide range of accessories and interfaces

- Quick deployment, operation and scalability

- GoControl Fleet Management System

- Open API and integration with WMS/ERP

- Support and Training

GoPal

What is the GoPal solution?

The GoPal solution is a complete and unique end-to-end automated material transportation solution for factories, production facilities and warehouses.

The GoPal Solution comprises robots (AMRs), various types of stations/interfaces to your existing infrastructure and fleet management software.

GoPal

Good for bu$iness

The benefits of automating your intralogistics are plenty: from greatly improving safety on the work floor, to reducing costs and transferring employees to perform more valuable tasks.

Deploying AMRs to automate internal material transport enables companies to minimize human error and to eliminate the risk of injuries to employees and damage to materials.

The GoPal solution has revolutionized intralogistics by supporting companies with material flow optimization without extensive staff training or significant changes to their workspace.

Learn more about all the benefits