Accessories

Our accessories include pallet stations, lift stations, conveyor stations, IO Boxes (auxiliary interfaces), physical/virtual buttons and much, much more.

This way, you can completely tailor your GoPal Solution to your exact needs - without having to worry about integrating to other components or systems.

Pallet Station

The Pallet Station is available in different sizes suited for normal Euro-pallets, combined industrial and normal Euro-pallets, as well as US/UK pallets.

The Pallet Station can be deployed either as a single (stand-alone) station or combined as multiple stations using expansion modules (see below).

GoPal AMRs supported:

GoPal Pallet AMRs

(E22/E24/E24W/U22W/U24W).

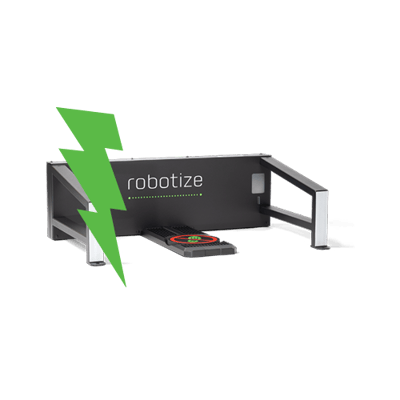

Charging Station (pallet AMRs)

Charging Station (platform AMRs)

Power transfer: Inductive (wireless).

Charge time: 45 minutes (30-95%).

As LFP batteries do not require special venting, the Charging Station can be deployed anywhere.

GoPal AMRs supported:

GoPal Platform AMRs

(P35).

Charging Station (Pallet AMRs)

Charging Station (Platform AMRs)

The Charging Station for our platform AMRs is inductive (wireless) and designed for quick and fully automatic charging of the GoPal platform AMRs in just 45 minutes.

As LFP batteries do not require special venting, the Charging Station can be deployed anywhere.

GoPal AMRs supported:

GoPal Platform AMRs

(P35).

Charging Station (for Platform AMRs)

The Charging Station for our platform AMRs is inductive (wireless) and designed for quick and fully automatic charging of the GoPal platform AMRs in just 45 minutes.

GoPal AMRs supported:

GoPal Platform AMRs

(P35).

Lift Station (EUW)

The Lift Station (EUW) is a column lift, which supports normal, half-, and industrial Euro-pallets, as well as US/UK pallets.

It is designed to be used as a workstation, usually at the end of the production line or end of a packaging line.

The integrated control panel makes it easy to lift pallets up/down and to call a GoPal AMR for pallet pick-up and delivery.

Operation: manual, semi-automatic and fully automatic.

Max. load: 1200 kg // 2600 lbs

GoPal AMRs supported:

GoPal Pallet AMRs

(E22/E24/E24W/U22W/U24W).

Mobile Lift Station

The Mobile Lift Station not only makes palletizing easy and safe, but also mobile. During palletizing, the design allows for easy and safe access to the pallet, as well as allowing the pallet height to be continuously adjusted from a height of 380 mm // 15 in to floor level – ensuring continuous optimum ergonomic working height.

And, as the name implies, the innovative design makes the lift station mobile, which means that it can be quickly moved to another part of the work floor - with or without payload.

Max. load: 300 kg // 660 lbs.

GoPal AMRs supported:

GoPal Pallet AMRs

(E22/E24/E24W/U22W/U24W).

Conveyor Station (E)

Conveyor Station (EW)

The Conveyor Station (EW) provides a seamless integration with PLC using a conventional pallet conveyor system.

The station enables the GoPal AMRs to deliver pallets to/receive pallets from existing conveyor systems.

Pallets types supported:

Standard Euro-pallets and industrial pallets

Max. load: 1500 kg // 3300 lbs.

Single Button

Device with a single button to manually request a GoPal for pickup-and-delivery to a preprogrammed destination.

LED-colors on the button indicate order status.

GoPal AMRs supported:

All GoPal AMRs.

Multi Button

Device with five buttons to manually request a GoPal for pickup-and-delivery to five preprogrammed destinations.

LED-colors on the buttons indicate order status.

GoPal AMRs supported:

All GoPal AMRs.

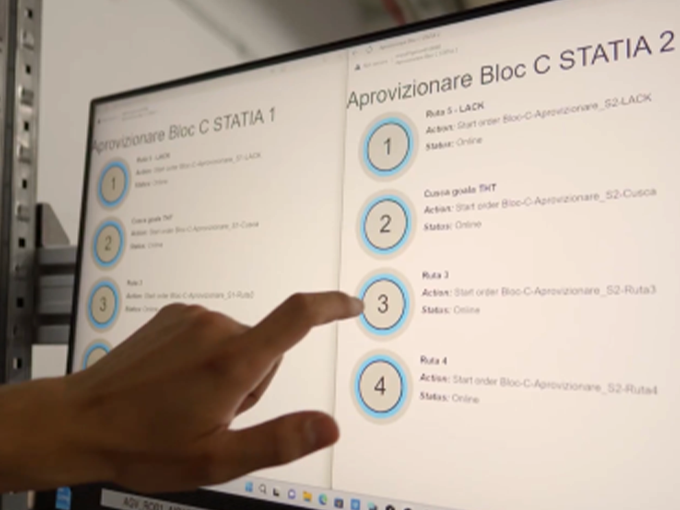

Virtual Buttons

Virtual buttons are presented on a touch-sensitive screen (e.g., tablet) or on a laptop/PC monitor.

LED-colors on the buttons indicate order status.

GoPal AMRs supported:

All GoPal AMRs.

Pallet Sensor

Pallet Sensors automatically detect the presence/absence of a pallet.

This way, GoControl always knows whether a given pallet station is occupied or empty. The Sensors can also be used to automatically trigger jobs and much more.

Pallet Sensors connect to the IO Box to communicate with GoControl.

GoPal AMRs supported:

GoPal Pallet AMRs

(E22/E24/E24W/U22W/U24W).

Warning Beacon

Warning Beacons provide an additional layer of safety and robot visibility on the factory floor.

Whenever the robot is in motion, the warning beacon flashes green.

GoPal AMRs supported:

All GoPal AMRs.

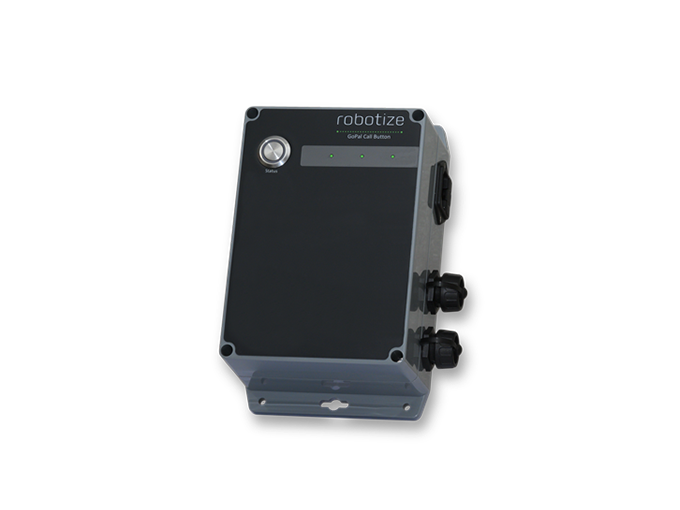

IO Box

The IO Box is an auxiliary interface with six Inputs/Outputs.

The IO Box connects GoControl to other Robotize devices (e.g., Pallet Sensors) as well as external systems (e.g., PLC systems, fire alarms, systems for automatically open/close gates etc.)